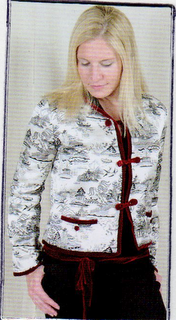

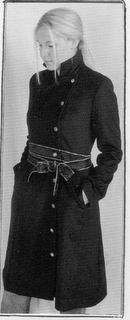

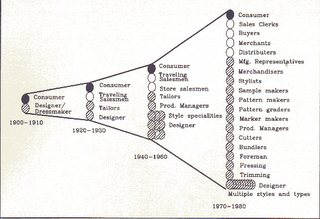

As an important reminder I will mention about S.E.L.F. structure on each blog post, that we are a Laboratory for research and solving problems in couture and high fashion design and production – for DEs and consumers all over the world – because you are the ones that need our help, and to whom I am committed. The same solutions can be used in lower priced apparel and big name manufacturers, but it is the high fashion market that desperately needs to learn quality yet also cost-effective ways of producing.I could give you many examples of bad shape/fit and poor workmanship on shape/fit on $2000 and up brand label apparel. But, if you truly want to sell and you’re not a “brand label”, then consider trying out our “S-Pattern” system. Yesterday’s blog post gave you a little on the S-Patterns for developing a fashion style. And in order to get these patterns you must learn first how to use them – in 3 learning lessons.

By January 6, 2007, we will have the first lesson on the web for you to do. You must email me of your interest to get the URL in an email reply.

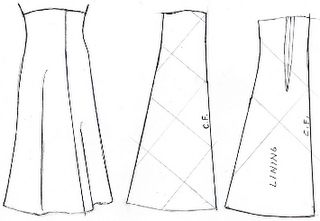

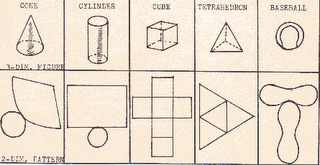

1) The first lesson is about learning to SEE inside your mind, the 2-D & 3-D translations, which is what creative pattern making is all about. That is my Stylometrics system which I spent years researching with grants from the National Science Foundation, and is a non-mathematical system. You must have experience in sewing clothing to comprehend the system. Hopefully you have the ability to send me some sketches of shapes you draw by email. If not, then you can send by regular mail.

2) The second lesson is the experience of manipulating a primitive pattern to a new shape, still a creative, observing methodology.

3) The third lesson is the experience of adding seam allowances in such a way that an industrial stitcher can make the style cost-effectively.

Some have been asking me questions, such as learning ways to get better fitting. This is way down the road, and there are many new things to learn first about a new system. “First things first” and “One step at a time”, are some philosophies to guide you. Remember that the S-Patterns are “standards”, that are used to evolve all styles, shapes, and fit from. It’s the key by which we can help you with every pattern evolved from it. I’ve had a university in Singapore quote and praise the concept in the mid-1990s. A CAD vendor in Germany in 2001 contacted me about using the Stylometrics system. We emailed back and forth, until I realized he wanted me to design a way to put my system on top of his CAD system. I said no way, being a “standard”, he had to design a way to put his CAD system on top of my pattern system. We failed to agree, and I now realize that it’s best to teach it to the young DEs and consumers, and forget old hat CAD vendors & apparel manufacturers.

Please email me and let me know your interest, so that as soon as the URL is ready I will send it to you. Meanwhile, have a Happy & Successful New 2007. Shirley